|

alfoil® PVdC-coated Films

High-performance and cost-effective line of PVdC-coated films

Pentapharm® alfoil® is a high-performance line of PVdC-coated films that provides a mid-to-high barrier to moisture, oxygen and aroma. Available in a wide range of coat weights and structures, alfoil® films are a cost-effective solution for most hygroscopic and oxygen-sensitive pharmaceuticals. Also available with kp’s proprietary Super Glide (SG) coating technology, alfoil® SG films have improved slip-characteristics that enable faster line speeds, higher yields and lower overall packaging costs.

Benefits

- Largest portfolio of coated films in the industry

- Only manufacturer with coating operations on four continents; global supply security with local service

- Super Glide (SG) PVdC technology for improved line performance and reduced overall packaging costs

- Reduced tooling corrosion (lower HCL)

alfoil® HBC - high-barrier coated films

The latest in ultra-high barrier PVdC technology

Benefits

- High-crystallinity PVdC for higher barrier at competitive cost

- Complete barrier protection from moisture and oxygen

- Superior cost-to-barrier performance vs PCTFE

- Symmetrical structures and alfoil® SG for increased line performance and lower overall packaging costs

- Increased crack-resistance and lay-flat properties vs standard PVdC

- Brilliant clarity for transparent blisters

|

|

ACLAR® laminated Films

Exceptional barrier protection

These multi-layer laminate films are highly transparent and clear. They offer excellent thermal stability and can be processed using standard equipment and tooling. ACLAR® films are chemically inert.

ACLAR® is a registered trademark of Honeywell International Inc.

Benefits

- Best-in-class moisture barrier

- Non-aging for lasting optical clarity

- Full range of barrier protection

- Possible 40% reduction in surface area of the blister allowing up to 30% higher machine output

- Runs on standard equipment and tooling

- Excellent sealability

- Available in clear, transparent, and opaque colors with UV-absorber on request

|

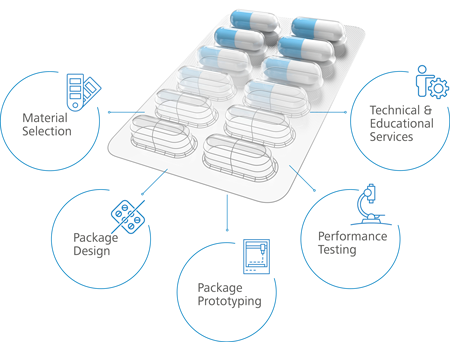

Do you find yourself in need of some help with a particular packaging problem? Maybe you are facing issues such as:

- Package barrier properties

- Chemical migration questions

- Forming solutions

- Product stability answers

- Regulatory concerns

If so, we provide a unique service called BlisterPro® XCEL where we use our packaging, materials, and design expertise to quickly guide you through to a workable solution.